Drying pallets for bricks

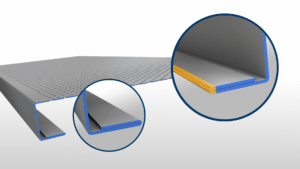

The production of the Stafier drying pallets for facing bricks and pavers is fully automated with the use of robots. Perforation, forming and spot-welding are performed in succession within the production process. Stafier supplies the right sort of drying pallets for every type of brick to allow quick drying of the green product so that energy can be saved. The size and design of the pallets are customer specific and therefore meet the customer requirements.

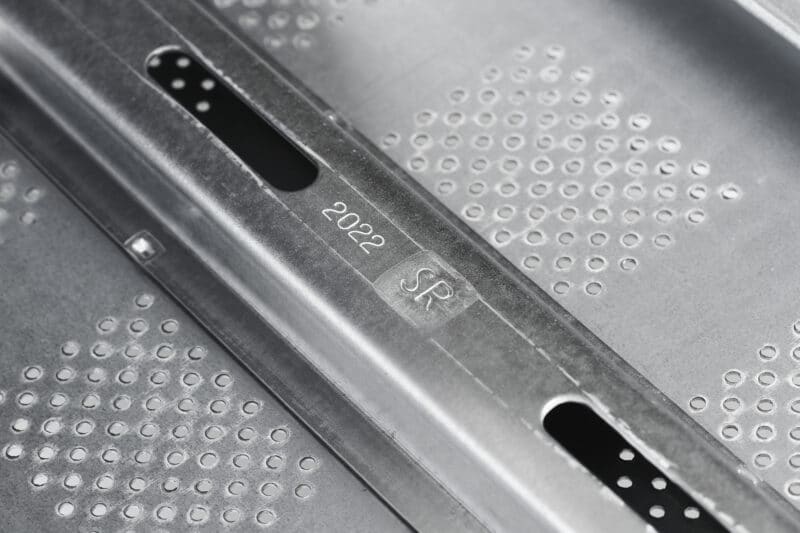

SR (Sound Reduced) drying pallet

With the development of this drying pallet Stafier has made a contribution to reducing the noise level in the brick factory. Stafier has been helped in this process by a Netherlands Institute for the ceramic industry, that carried out tests on the SR drying pallet. The stiffener profile of this brick drying pallet is insulated, to reduce acoustic energy transmission by 50%. An international patent has been granted for the SR drying pallet.

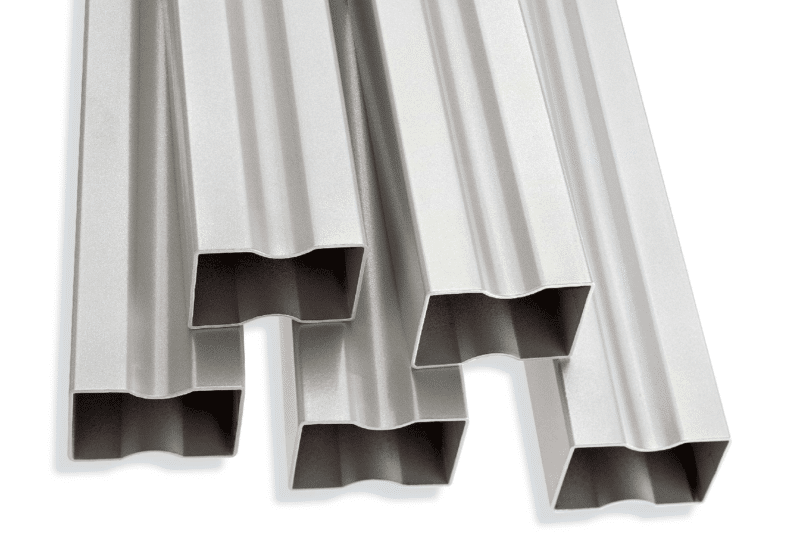

DFM (Double Folded Material) drying pallet

This drying pallet has a reinforced bottom edge with rounded corners. It increases resistance to deflection.

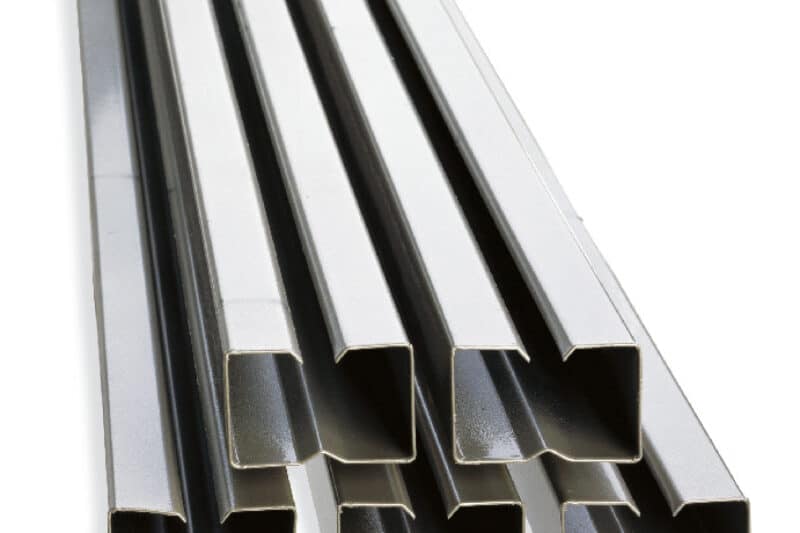

Drying laths

Stafier designs and produces many types of drying laths and profiles including for use with extrusion bricks and blocks/chunks. The laths are made from a variety of types of materials, such as galvanized steel, aluminium and stainless steel depending on the system requirements and the drying atmosphere used by the customer. As well as the usual open laths Stafier also supplies the very stable closed laths, with or without perforations.