Stafier, past en present

Stafier was founded by the brothers Stef and Jan Fierkens (STAmperij FIERkens). They made dies and moulds, mainly for the stove industry. Due to the mechanization in the brick industry the product range was extended with perforated drying pallets as a replacement for wooden boards. Later, the production of supports for drying systems in the tile/roof tile industry, the food industry, the roof-integrated BIPV solar panel and other industries was added. And so a very extensive and diverse product portfolio was created.

In the village of Herwen, Stef Fierkens starts his tool shop

in the Koetshuis of ‘Huize Aerdt’ Castle.

Brother Jan continues the little stamping plant in the apple shed

of the Mariahoeve in Lobith.

Jan Fierkens registers Stafier at the Chamber of Commerce as a stamping plant and is then a supplier to the sheet metal industry. His brother Richard continues with the tool shop in the Koetshuis under the name Fico and produces dies and moulds.

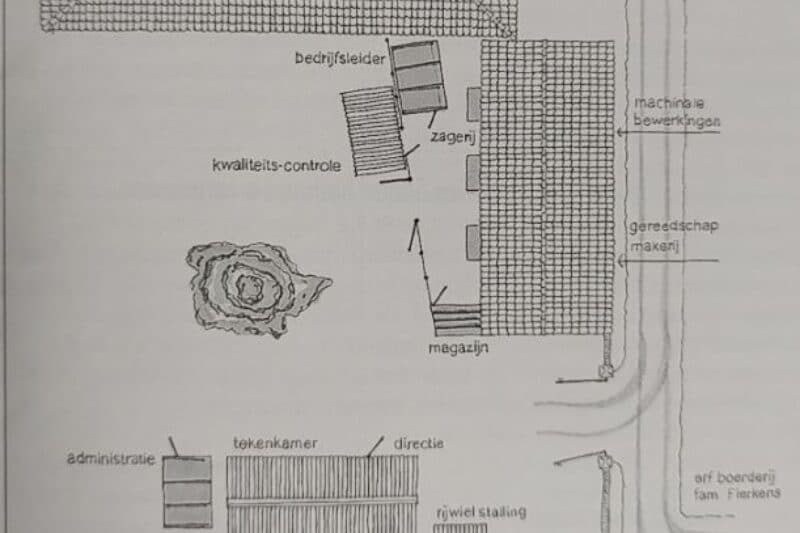

Stafier moves to a new building and its position grows into that of supplier for the ceramic industry in the Netherlands and Belgium. Export becomes more and more important and Stafier takes its first steps into the foreign markets in Europe. In addition to products for the ceramic industry, the company also develops new products for the Dutch dairy industry, such as stainless steel cheese shelves.

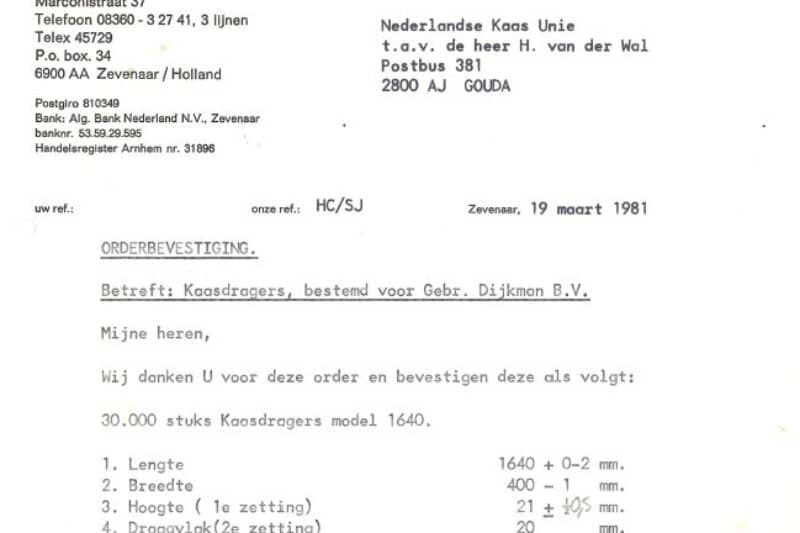

The first delivery of cheese shelves: 30,000 pieces for

the Nederlandse Kaas Unie.

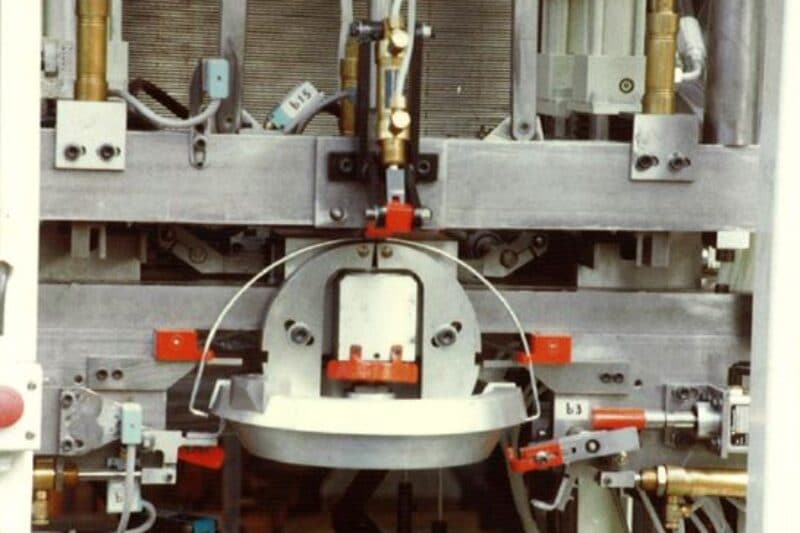

Stafier builds and sells machines that produce bucket brackets and which also put the brackets right on the buckets.

The premises have become too small for all the offices.

An extra part is built on.

This doubles the total company surface area. Stafier’s market share expands to North and South America, Australia, the Middle East and Africa.

Stafier sells the wire division to Redfearn UK and focuses entirely on sheet metal. The purchase of the Salvagnini folding line gives Stafier an enormous advantage over the competition in terms of technology and cost price.

The first solar panel comes about through an international collaboration between 5 countries called Project Starlet. They are all roof tile manufacturers who commission Stafier to develop a solar panel. It results in a BIPV (roof-integrated) module. The group of manufacturers may not start their own sales initiatives for 5 years. Stafier immediately provides the panel with ventilation holes and patents it in order to be ahead of the competition. A true USP!

To improve welding quality and production speed, Stafier invests in a new welding machine.