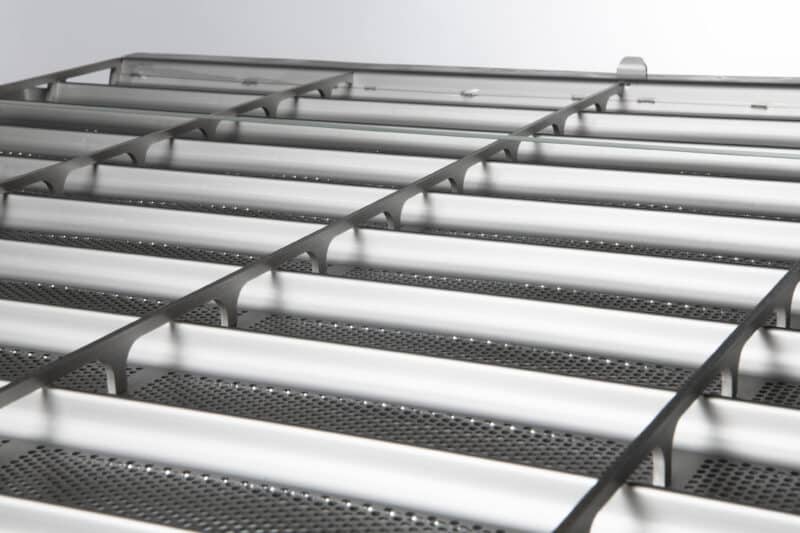

Sterilization trays

Save costs without losing quality

Optimize your production line with sterilization trays

In a production line, even the smallest adjustments can result in major improvements and cost savings. Think of the right sterilization trays and a partner who thinks along with you from the first design. This way you will benefit from:

- Reduction of energy costs

- Optimization of the production process

- Speeding up of the production time

Rule out any risks: go for a trouble-free process

Sterilizing food is a precise process. You want to guarantee food safety and you want to prevent production line downtime at all times. It’s a no-brainer, because this would not only cost a lot of money, it also puts your company’s reputation at stake. This is why it pays to look at optimizations in the production line. For example, there is much to be gained by taking a close look at your sterilization trays. Stafier can help you with this, and you will benefit from our many years of experience. We use this knowledge when we’re making sterilization trays for customers all over the world.

Choose a partner with its own engineering department

A partner with its own engineering department is indispensable. The experts in this department make a design to optimize your current sterilization trays to save energy and speed up the production process. The designs are based on semi-automatic or fully automatic handling solutions. For us, having our own engineering department is an important part of the process. Our engineers like to get their teeth into the most complex issues. And that’s being appreciated, because for years, renowned, international companies know where to find us.

The advantages of optimized sterilization trays

Cost savings and sustainability

Reduce costs through efficient energy use

Reliability and continuity

Prevent downtime of the production process and speed up production time

Future-proof

Modernize the production line and be prepared for the future.

Sterilization trays for each production line

Every production line is unique. Our sterilization trays are tailored to achieve the most optimal result. We do this for continuous, batch and pilot retorts, among others. We take into account your specific Autoclave in the design. Think of static, rotating or oscillating retorts, steam and water spray or a combination of both, cascade water systems and heat distribution.

Our custom sterilization trays are:

- suitable for all containers, including flexible pouches

- made from high quality stainless steel, which guarantee a perfect surface condition

- suitable for any type of autoclave, any size possible

- problem-free useable in any handling system

- Seamlessly integratable into an existing production process

Our working method

Every day we work on the most complex challenges. This is how we help companies grow. Our team of engineers thinks along with you from the very first moment. What opportunities and optimizations are there? How can the sterilization process be made more efficient? These are just a few of the issues our technical people are working on.

We have the production in-house, so we can follow the process closely. Because only by leaving nothing to chance do we ensure that we can give you the very best product. And if you have any questions, then we are also here for you.